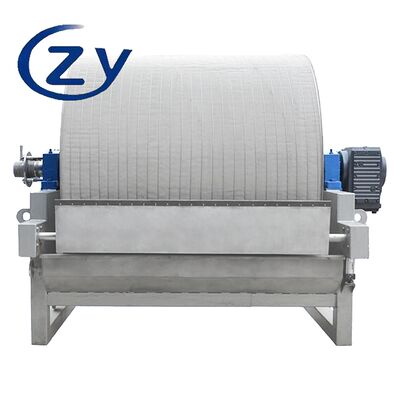

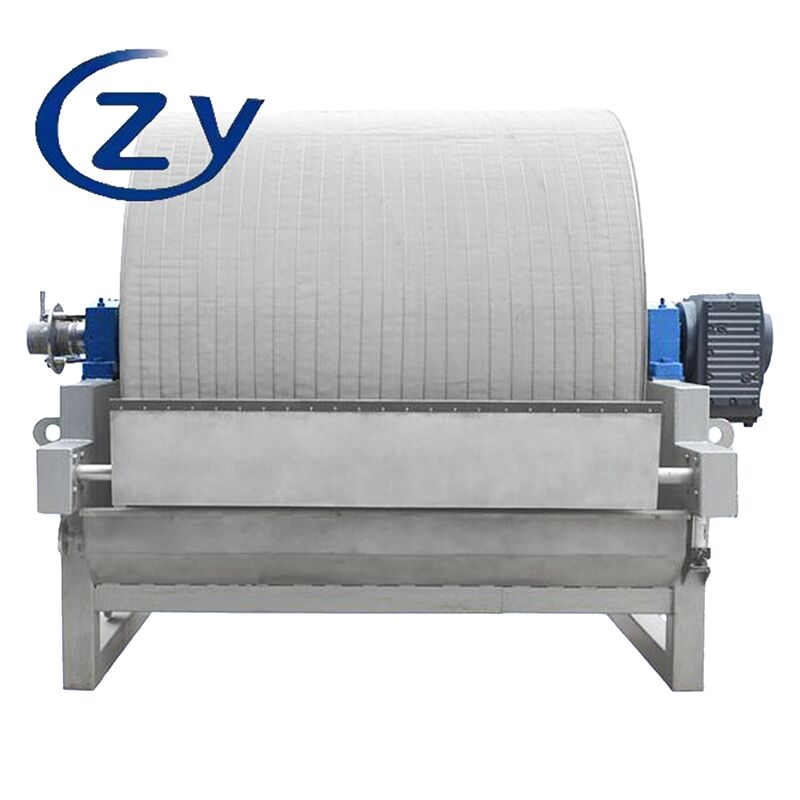

Großvolumen-Rotations-Vakuumtrommelfilter - Hochreinigungsmaschine zur Entwässerung von Kartoffelstärke und -schlauch für die Lebensmittelverarbeitung

Produktdetails:

| Herkunftsort: | China |

| Markenname: | ZY |

| Zertifizierung: | ISO |

| Modellnummer: | VM10 |

Zahlung und Versand AGB:

| Min Bestellmenge: | 1 Satz |

|---|---|

| Verpackung Informationen: | Einfache Verpackung |

| Lieferzeit: | 20–30 Tage |

| Zahlungsbedingungen: | L/C, T/T |

| Versorgungsmaterial-Fähigkeit: | 20 sätze pro monat |

|

Detailinformationen |

|||

| Material: | SS304 | Leistung: | 4KW |

|---|---|---|---|

| Kapazität: | 2-8 t/h Trockenstärke | Garantie: | 1 Jahr |

| Farbe: | Silbrig weiß | Stromspannung: | 308v50Hz |

| Dienstprogramm: | Stärkeentwässerung | Name: | Maschinen und Apparate zur Herstellung von Süßkartoffelstärke |

| Anwendbare Branchen: | Lebensmittel- und Getränkefabrik | Rohstoff: | Maniok, Kartoffel, Süßkartoffel |

| Maschinenmaterial: | Edelstahl | Verpackung: | Standardverpackung |

| Brand name: | ZY | ||

| Hervorheben: | mit einer Breite von mehr als 20 mm,potato starch slurry dewatering machine,Maschine zur Entwässerung von Kartoffelstärke-Schlamm |

||

Produkt-Beschreibung

Kartoffelstärke-Dehydratationsfilter mit integriertem Antriebsmotor für Kartoffelstärke-Fertigungsanlagen

Beschreibung der Maschinen zur Herstellung von Süßkartoffelstärke:

Eine Vakuumtrommelfilterpresse besteht aus einer rotierenden Trommel, die in einem Sumpf, der die Schlammfilterung enthält, arbeitet.Die Vakuumaufnahme zieht die Flüssigkeit und die suspendierten Feststoffe auf das vorbeschichtete Filtermedium der TrommelDie flüssige Fraktion wird durch das Filtermedium mit Vakuumkraft gezogen, innerlich in die Trommel gesammelt und dann ausgestoßen.Der auf der Außenseite der Trommel gebliebene feste Kuchen wird zu einer Schraubanlage transportiert, wobei es zusammen mit einer dünnen Schicht des Filtermediums abgeschraubt wird, wodurch eine frische Filteroberfläche für den nachfolgenden Filtrationszyklus freigesetzt wird, während die Trommel weiter dreht.

Durch die kontinuierliche Weiterentwicklung des Filtrationsprozesses und der Filtrationstechnik als einer der wenigen Zulieferer erlangte ZY eine führende Marktposition

![]()

Arbeitsprinzip:

Diese Stärkeentwässerungsmaschine nutzt die Saugkraft einer Vakuumpumpe, um einen negativen Druck im Inneren der Trommel zu erzeugen, wodurch die Stärke an dem Filtertuch der Trommel haften bleibt.Während sich die Trommel kontinuierlich bei niedriger Geschwindigkeit dreht, bildet sich auf dem Filtertuch eine starke Schicht einer bestimmten Dicke.und die Stärke wird automatisch durch einen Schaber abgeschraubt, wodurch eine effiziente Stärke-Entwässerung erreicht wird.

Typ der Stärkeentwässerungsmaschine:

| Typ | VF10 | VF15 | VF20 |

| Filterfläche | 10 m2 | 15 m2 | 20 m2 |

| Macht | 5.5 kW | 11 kW | 18.5 kW |

| Kapazität | 2 t/h | 4 t/h | 5 t/h |

Häufige Fragen:

1Sind Sie die Hersteller oder Handelsfirma?

A: Wir sind der Hersteller mit professionellen Produkte Erfahrung auf Stärke Maschine und Design mehr als 13 Jahre.

2Wo ist Ihre Fabrik?

A: Unsere Fabrik befindet sich in Zhengzhou Stadt, Provinz Henan, willkommen zu besuchen.

3Was ist Ihre Garantie für die Maschine?

A: Gewöhnlich ist unsere Garantie 1 Jahr.

4Können Ihre Techniker die Maschine installieren?

A: Ja, wir werden unsere Ingenieure beauftragen, ins Ausland zu gehen, um Maschinen für unsere Benutzer zu installieren.

5- Was ist die Mindestbewegungsfähigkeit?

A: Bei der Maschine zur Herstellung von Maniokmehl beträgt die Mindestkapazität 1 t/h Mehl pro Stunde.

B: für die Maniokstärke: die Mindestkapazität beträgt 2 Tonnen Stärke pro Stunde.

![]()

Werkstatt der Stärkefabrik:

![]()