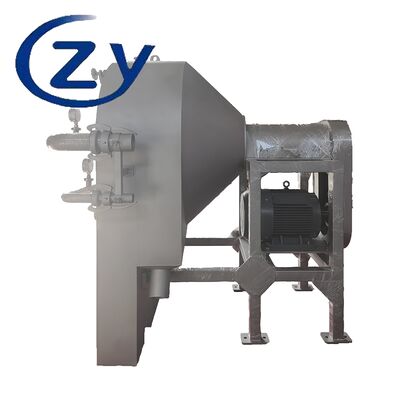

Präzisionszentrifuge Siebe Stärke Milch Klärmaschine für die groß angelegte Verarbeitung von Wurzeln

Produktdetails:

| Herkunftsort: | China |

| Markenname: | ZY |

| Modellnummer: | CS850 |

Zahlung und Versand AGB:

| Min Bestellmenge: | 1 Satz |

|---|---|

| Preis: | 2000-999999USD |

| Verpackung Informationen: | Holzkiste |

| Lieferzeit: | 30 Tage nach Zahlung |

| Zahlungsbedingungen: | L/C, T/T |

| Versorgungsmaterial-Fähigkeit: | 30 sätze pro monat |

|

Detailinformationen |

|||

| Farbe: | Silberweiß | Qualifikation: | ISO/CE |

|---|---|---|---|

| Garantie: | 1 Jahr | Material: | Edelstahl |

| Motor: | seimens und china marke | Vorteil: | Hohes leistungsfähiges |

| Rohstoff: | Maniok, Kartoffel, Süßkartoffel | Funktion: | Hochleistungs-Kernschleifmaschine |

| Stromspannung: | Gemäß lokaler Spannung | Wechselrichter: | Delta, Simens |

| Betrieb: | Vollautomatische Fräsmaschine | Anwendbare Branchen: | Lebensmittel- und Getränkefabrik |

| Hervorheben: | Präzisionszentrifuge-Siebe-Stärke-Maschine,Maschine zur Verarbeitung von Wurzelpflanzen,Maschine zur Klärung von Cassava-Stärkemilch |

||

Produkt-Beschreibung

Präzisionszentrifuge Siebe Stärke Milch Klärmaschine für die groß angelegte Verarbeitung von Wurzeln

Beschreibung des Produkts:

Cassava-Zellstoff gelangt durch ein speziell gebautes Futterrohr in den unteren Bereich des Zentrifugalsiebkorbs.Die Zellstoffzelle verteilt sich gleichmäßig über die Präzisionsbildschirmoberfläche und bewegt sich in einem anspruchsvollen gekrümmten WegNach einer umfassenden Spülung mit Druckwasser durchlaufen Stärkepartikel, die kleiner als die Maschengröße sind, reibungslos den Sieb,während Verunreinigungen mit großem Durchmesser und faserförmiger Abfall effizient durch eine spezielle Schlackenentfernungspumpe entsorgt werden.

Leistungsmerkmale:

- Hochgeschwindigkeitsbetrieb leistet eine beispiellose Effizienz bei der Stärke-FaserabtrennungDie Präzisionskonstruktion der Ausrüstung gewährleistet eine gleichbleibende, zuverlässige Funktionalität und maximiert den Gesamtverarbeitungsdurchsatz für industrielle Anwendungen.

- Durch eine robuste, verschleißbeständige Konstruktion werden die langfristigen Wartungskosten minimiertund reduziert die nicht geplanten Betriebsausfallzeiten erheblich, wodurch die Wirtschaftlichkeit der kontinuierlichen Produktionslinien verbessert wird.

- Das System eignet sich hervorragend für die Großindustrieund umfangreiche kontinuierliche Verarbeitungsarbeiten, die sich nahtlos an die hohen Anforderungen der rund um die Uhr laufenden Stärkeproduktionsprozesse anpassen.

Maschinentyp:

| Modell | Durchmesser des Korbs | Arbeitsmodell | Leistung kw | Gewicht T |

| CS850 | 850 mm | Weiter. | 15 kW bis 30 kW | 1.3 |

| CS1000 | 1000 mm | Weiter. | 22 kW bis 37 kW | 1.5 |

| CS1200 | 1200 mm | Weiter. | 30 kW bis 45 kW | 1.8 |

- Ultra-Hochgeschwindigkeitsbetriebssystem: Durch die Rotation durch Flammen wird eine schnelle, anpassungsfähige Stärkefasertrennung ermöglicht.

- Präzisionskalibrierte Struktur: Optimierte Konstruktion sorgt für einen stabilen, langlebigen Einsatz bei schweren Einsätzen.

- Schwerlastfähige, verschleißbeständige Bauweise: Verschleißsichere Materialien senken die Wartungskosten und steigern den Nutzen.

- Anpassungsfähigkeit für die Industrie: Einstellbare Einstellungen unterstützen eine 24/7-Produktion mit hohem Durchsatz.

Innenbild für Zentrifugalsiete:

![]()